2025 · FOUNDER, LEAD DESIGNER

Plinth Press Base

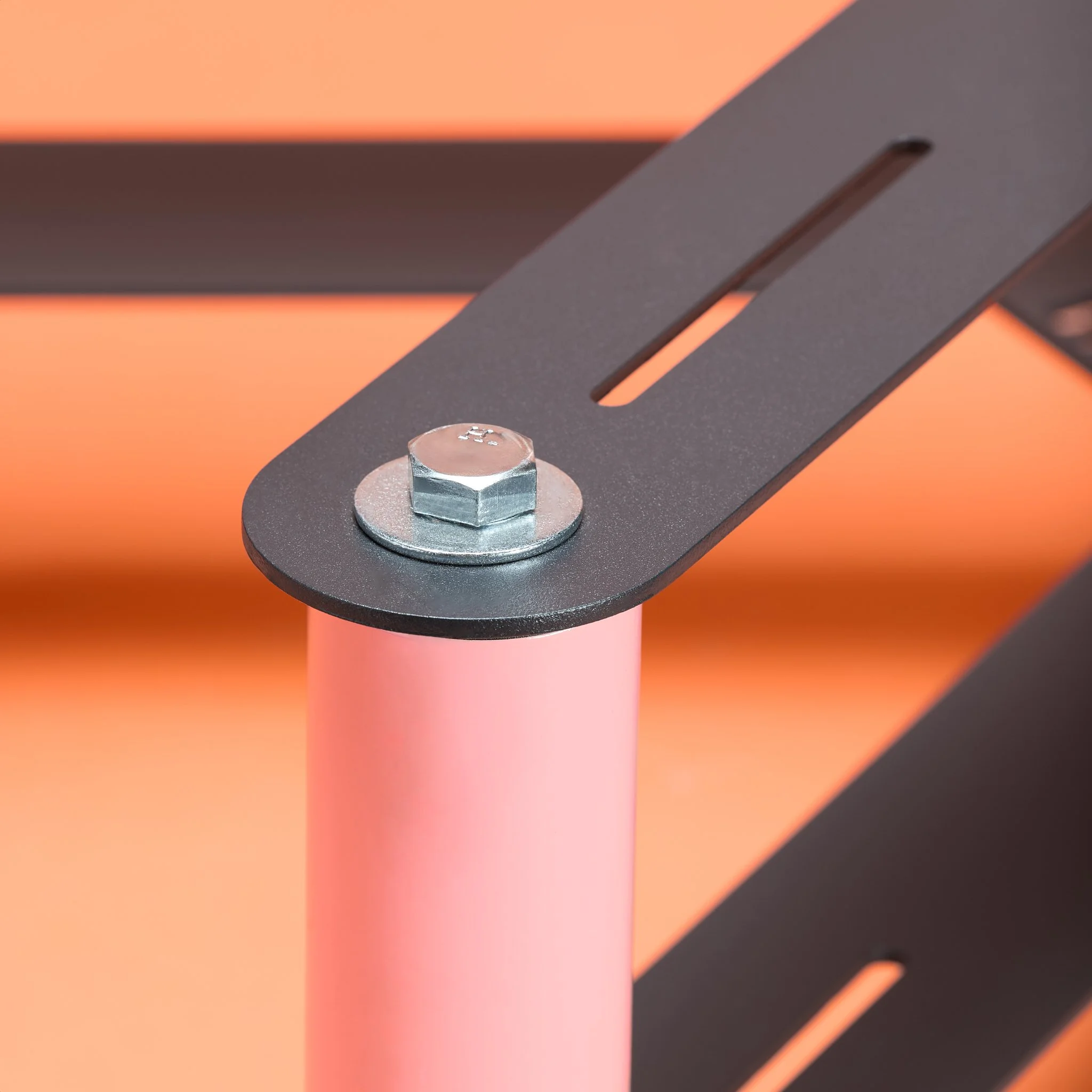

A sturdy, mobile base for basket presses. I led this product from concept through launch, coordinating hardware engineering, manufacturing, and go-to-market strategy.

Quick Facts

Timeline · 18 months

Role · Founder, Lead Designer

Manufacturing · 5 partners across the US

Opportunity

When Improvisation Becomes Dangerous Home winemakers elevated their basket presses for better juice collection into standard buckets. DIY solutions, like mounting to folding tables, or tree stumps are too much hassle, immobile, and can be dangerous.

What's Broken:

No purpose-built stands for home winemaking scale

Makeshift solutions compromise safety and efficiency

Presses can't move once loaded with grapes

Wrong height = spilled juice and wasted batches

Cleanup means complete teardown every time

The Opportunity: Design a mobile press stand with precise bucket alignment, commercial-grade stability, and effortless cleanup - transforming the most physically demanding part of winemaking into a controlled, efficient process.

Brief

Functionality - A press base needed to be mobile when needed but stable and secure when pressing

Low-Volume Manufacturing - The realities of small batch manufacturing meant careful coordination of material choice, manufacturing methods, and design

Aesthetics - The Plinth Press Base expands the visual vocabulary of hobbyist tools, elevating the experience

Functionality

Solving Contradictions Plinth needed to be effortlessly mobile and absolutely immovable. These requirements directly contradict each other.

Height + Mobility Engineering:

Calculated optimal elevation for basket press + 5-gallon bucket pairing

Designed base geometry to minimize footprint while maximizing stability

Created a mounting solution that works across different bucket and press brands

Tested and selected high-strength caster wheels with a single-button lock for both rolling and swivel

The Result: Instant transition from mobile to rock-solid with a single foot press. Perfect juice flow into buckets, not onto floors.

Low-Volume Manufacturing

Making It Real Premium quality at accessible pricing required strategic manufacturing decisions from the start.

Material Strategy:

Powder-coated steel: corrosion-resistant and durable

Standard gauge materials available from local suppliers

Component selection from industrial catalogs (casters, hardware)

Production Approach:

Designed around sheet metal fabrication capabilities

Created flat-pack potential for efficient shipping

Avoided custom tooling throughout

Partnered with local manufacturers for quality control and iteration

Design for Manufacturing:

Simplified part count without compromising performance

Used standard hole patterns and fastener sizes

Designed tolerances that balance precision with practical fabrication

Created assembly sequence that works at both prototype and production scale

Built in serviceability: replaceable casters, accessible hardware

The Balance: Engineering excellence within the constraints of small-batch production economics.

Aesthetics

Beyond Utility Home winemaking deserved equipment that matched the sophistication of the craft. Plinth rejects the "good enough" aesthetic of typical hobby tools.

Visual Strategy:

Refined geometry and proportions vs. crude industrial forms

Thoughtful material expression: premium powder coat, quality welds

Structural honesty - framework celebrates its engineering

Compact, intentional presence in the cellar

Details that communicate care: smooth edges, considered joints

Breaking Convention:

Most hobby equipment prioritizes cheap over considered

Industrial tools ignore residential contexts

DIY solutions embrace improvisation aesthetically

Plinth positions home winemaking as serious craft deserving serious tools

The Statement: Equipment can be both functionally excellent and visually refined. Great design makes tools you're proud to own and use, not just tolerate.

Outcome

Engineering Meets Craft Plinth redefined what home winemaking equipment could be. Launching February 2026, patent filed November 2024.

Core Innovations:

Precision height for perfect bucket alignment

One-press stability system for 250+ lb loads

Low-volume manufacturing strategy delivering premium quality

Aesthetic refinement that elevates craft tools beyond utility

Lifetime warranty backing generational design

Design Contribution: Established that serious craft deserves serious tools - not industrial equipment scaled down, but purpose-built infrastructure designed for home winemakers. Plinth makes professional-quality pressing accessible while respecting both the craft and the maker's space.